The last news

-

201808Enfin le saint Graal !

Cela faisait un moment que je souhaitais me stabiliser sur la région toulousaine et c'est maintenant chose faite. A compter du 4 juin 2018, je serais dorénavant ingénieur responsable de lot électrique du matériel roulant pour la prochaine génération de métro automatique de Siemens: le Neoval.

Cette expérience supplémentaire vous montrera, je l'espère ,qu'un ingénieur peut être performant et efficace dans plusieurs secteur industriel à la fois sans forcément n'avoir évolué que dans un seul domaine d'activité.

Pour la première fois de ma carrière, j'évoluerais donc dans une entreprise autre que celle du conseil. Je vous invite à en découvrir tous les détails de ce nouvel emplois dans le menu emplois > Siemens. -

201617Une page se tourne

Passés les 16 mois de dur labeur, j'ai enfin pu mettre en pratique mes expériences et montrer ma réactivité dans un nouveau secteur d'activité qui est la Défense mais aussi et surtout le Spatial, le client final étant le CNES.

Ma mission étant arrivée en fin de développement, aujourd'hui je cherche plus de stabilité auprès d'industiels variés mais tout aussi technique sur l'étude et le développement de produits mécatroniques.

J'aurais tout de même un souhait supplémentaire. Celui de prendre plus de responsabilité sur le pilotage et le management de groupe de travail afin d'obtenir idéalement un poste de chef de projet.

Bonne lecture et n'oubliez pas, je suis à votre écoute. -

201410Partir à l'international

Après quelques années à chercher ma voie sur les activités professionnelles dont je souhaiterais faire évoluer ma carrière, je souhaite donner une nouvelle dimension internationale à celle-ci.

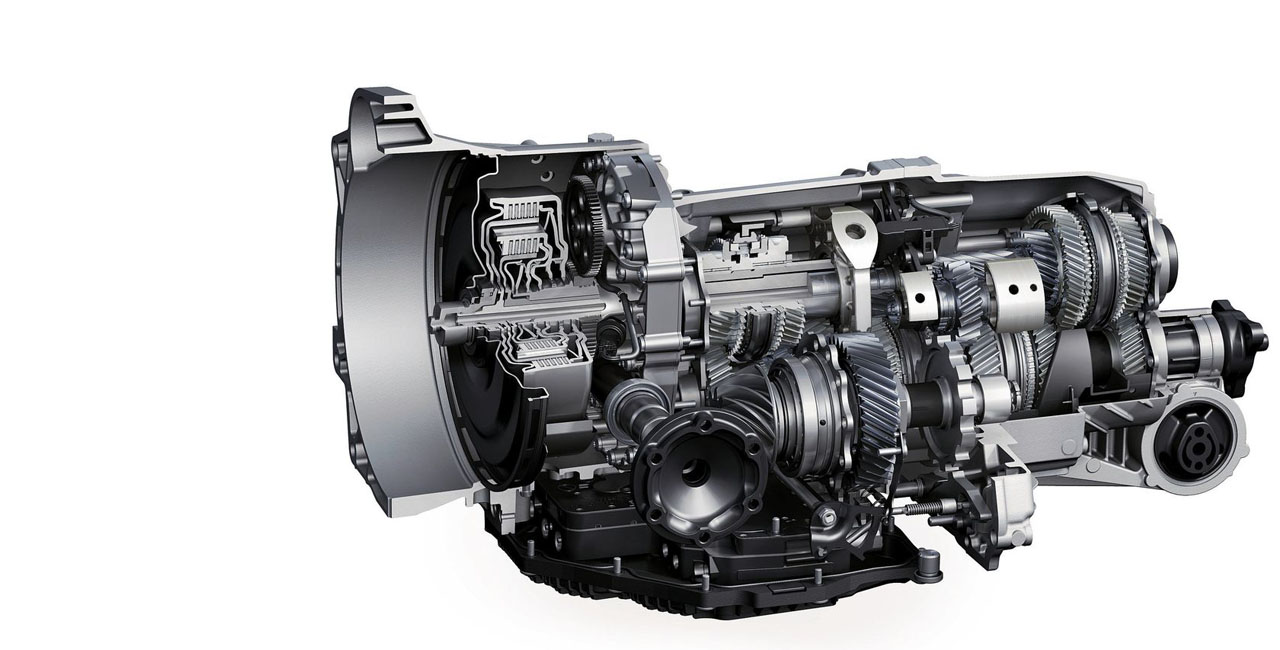

Mon dernier poste au sein de Borgwarner qui possède une telle structure m'a permis d'évoluer en ce sens. Etant donné que ma mission se termine é la fin de l'année et que le goût de l'aventure est toujours dans mon esprit, c'est donc tout naturellement que je me tourne aujourd'hui vers l'étranger.

Si vous êtes intéressé par mon profil et que vous avez un poste d'ingénieur responsable design produit dans un pays autre que la France, n'hésitez pas à me contacter via la rubrique contact!! -

201230Un nouveau design pour une nouvelle vie !

Le temps avance à vitesse folle et la technologie aussi. Le HTML 5 est déjà bien encré sur le web et comme je ne voulais pas vous faire de peine, j'ai moi aussi optimisé mon site. J'en ai profité pour lui refaire une beauté rien que pour votre plus grand bonheur...(ou le mien)

Ainsi vous pouvez bénéficier d'une meilleure présentation plus claire des informations et un outil très pratique de partage en ligne vers vos réseaux sociaux les plus utilisés et même ceux qui passent inaperçus.

Si vous souhaitez me faire partager des remarques, des impressions ou des améliorations, n'hésitez pas à me contacter via le lien "contact" situé en bas de page. -

200803En quelques mots...

Après une école préparatoire aux grandes écoles en filière PCSI-SI, l'ENSIL (Ecole Nationale supérieure des Ingénieurs de Limoges) m'a formé au sein de sa filière "Mécatronique".

Ces 3 ans de spécialisation dans les matières principales: mécanique, électronique, automatique, informatique, etc... m'ont permis de découvrir le monde de la conception et du développement industriel dans les domaines principaux de l'automobile et de l'aéronautique.

Ce site a pour vocation d'afficher les résultats de mes projets professionnels entrepris. En espérant que son contenu vous intéresse...

Bonne visite !